Revolutionizing Plastic and Rubber Processing: Carrier Vibrating Equipment’s Innovative Solutions

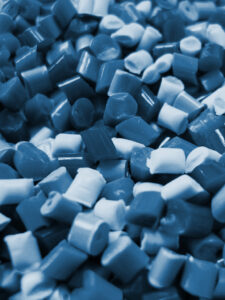

Plastic and rubber have completely changed the world and makeup products people use constantly. Plastic and rubber production requires exact temperatures and moisture levels to ensure quality and reduce the rate of defects and issues. High-quality custom processing and drying equipment from Carrier Vibrating Equipment is built to meet the specific needs of each production line.

Carrier’s plastic processing equipment can dry and process plastics, including acrylic, PET, polyurethane, polycarbonate, nylon, polyethylene, polypropylene, polystyrene, PVC, and crumb rubbers.

Vibrating Fluid Bed Dryers

Vibrating fluid bed dryers are ideal for processing temperature-sensitive plastics and rubber since the product is continually mixed to promote uniform drying. The size and length of the fluid bed can be engineered to control the moisture level and temperature to reach the required levels.

Spiral Elevators

Spiral elevators are ideal for cooling or processing plastic and rubber in a small footprint, and the constant motion of the product means there will be no clumping or uneven drying and cooling that would be found in a conveyor belt or bucket elevator.

Vibrating Conveyors

Vibrating conveyors can eliminate bed matting through the vibration angle of attack and can be made with non-stick coatings to keep rubber and plastic from sticking and keep equipment clean between batches. Custom conveyors can perform processing such as quenching, dewatering, screening, spray washing, cooling, drying, distributing, and feeding.