Waste Recycling: Innovative Equipment for Efficiency and Sustainability

The world creates massive amounts of waste material, but luckily, large portions of that can be recycled and made into something that can be used repeatedly. Carrier Vibrating Equipment has a line of waste processing equipment designed specifically for the recycling industry’s unique needs while providing the highest efficiencies to keep costs down and revenues up.

Vibrating Conveyors

Light-duty and medium-duty vibrating conveyors are perfect for handling and moving paper, cardboard, glass, and plastics. Quenching conveyors are used for glass cullet, and dewatering conveyors are used after washing plastics. Our conveyors can also be designed to dry, cool, orient, separate, and distribute.

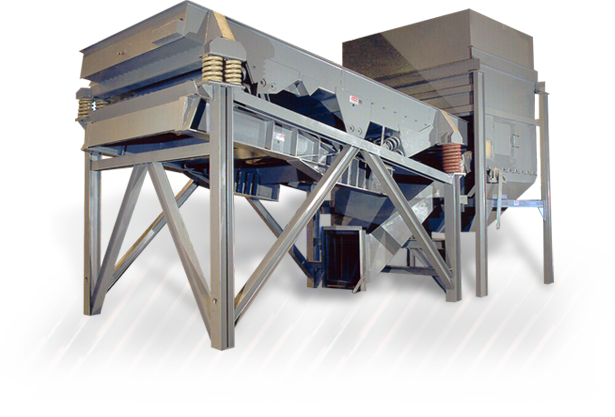

Screeners

Screeners are built for wet and dry screening, can be engineered with custom deck designs to fit the exact requirements, and can have up to five screens on a single unit.

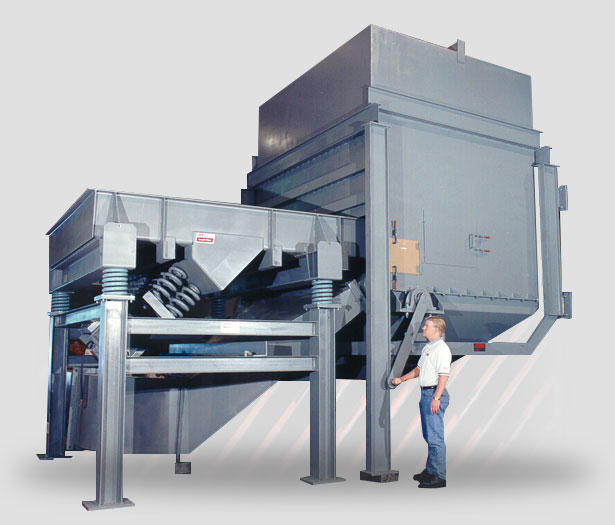

Air Knife Separators

Air knife separators are an efficient and easy way of separating metal, plastics, plastic, and debris from the waste stream. This helps to reduce the contaminant levels in recycled alloys and paper and plastic bales. The air knife uses a vibrating conveyor to move material over a high-velocity stream of air, causing heavy materials to fall to the bottom while lighter materials are blown into a hopper or exhaust filter.

Fluid Bed Dryers

Fluid bed dryers are an ideal and customizable solution for efficiently removing moisture from recycled materials that may otherwise cause issues with processing. Anything from UBC aluminum scrap must be dried before going into the furnace to plastics that have been cleaned and washed; a fluid bed dryer can be designed for any material and moisture requirements.