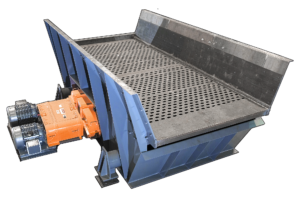

Carrier Delta-Phase® shakeout machines efficiently shake out castings and reduce sand lump size.

Our Delta-Phase shakeouts (patent #5,615,763) use a unique vibratory motion to separate sand from castings, allowing sand to pass through a perforated deck and castings to end discharge for further processing. These shakeout machines allow for precise control over the angle of vibration, optimizing the removal of sand, even when the machine is in-use.

Heavy-duty Feeders by Carrier are expertly designed to maintain stroke under extreme loads, delivering an exact flow to ensure efficiency and safety. Carrier’s Vibrating Screeners are designed to screen, scalp, dewater, or separate materials

Delta-Phase Shakeout Process Controls

The heart of the Delta-Phase Shakeout is the process controller. Using simple and reliable electronics, the Delta-Phase shakeout machine is able to precisely control the angle of vibration. This change in vibration angle controls the conveying speed and retention time of your castings on the shakeout deck, optimizing sand removal. You can accurately and automatically change this angle – even on the fly!

![]() Read how a client solved his production problems, while saving costs and time, with a Carrier patented Delta-Phase® Shakeout Safer Shakeout Article

Read how a client solved his production problems, while saving costs and time, with a Carrier patented Delta-Phase® Shakeout Safer Shakeout Article

![]() Case Study: Foundry updates operation with a new Delta-Phase® Shakeout and other heavy-duty equipment.

Case Study: Foundry updates operation with a new Delta-Phase® Shakeout and other heavy-duty equipment.

Features and benefits of Carrier Delta-Phase shakeout machines:

- Patented Delta-Phase shakeouts provide ultimate process control.

- Available in low, medium and high frequency designs with direct drive force or natural frequency designs.

- Used for sand to metal ratios as low as 5:1 and as high as 60:1.

- Direct drive design prevents overstroke during upset conditions caused by wet, sticky sand.

- Natural frequency designs handle heavy duty applications with very low energy consumption.

- Mounted on soft isolation springs to reduce the dynamic reaction transmitted to the foundation.

- Barrel Horse™ shakeout machine provides the above features while gently blending the molding sand with the castings. Also provides homogeneous, conditioned sand and cool, clean castings. Extremely useful handling fragile castings commonly damaged by rotating drum shakeouts.

Other Heavy-Duty Foundry Equipment From Carrier Vibrating

- Conveyors

- Shakeouts

- Feeders & Screeners

- Barrel Horses

- Attrition Mills / Lump Breakers

- Furnace Charge Feeders

- Sand Coolers

- Spiral Elevators

For more information on Carrier shakeout machines, refer to brochures CVE-FND-0422.